By:

VNC Automotive

Date:

31st Jan 2024

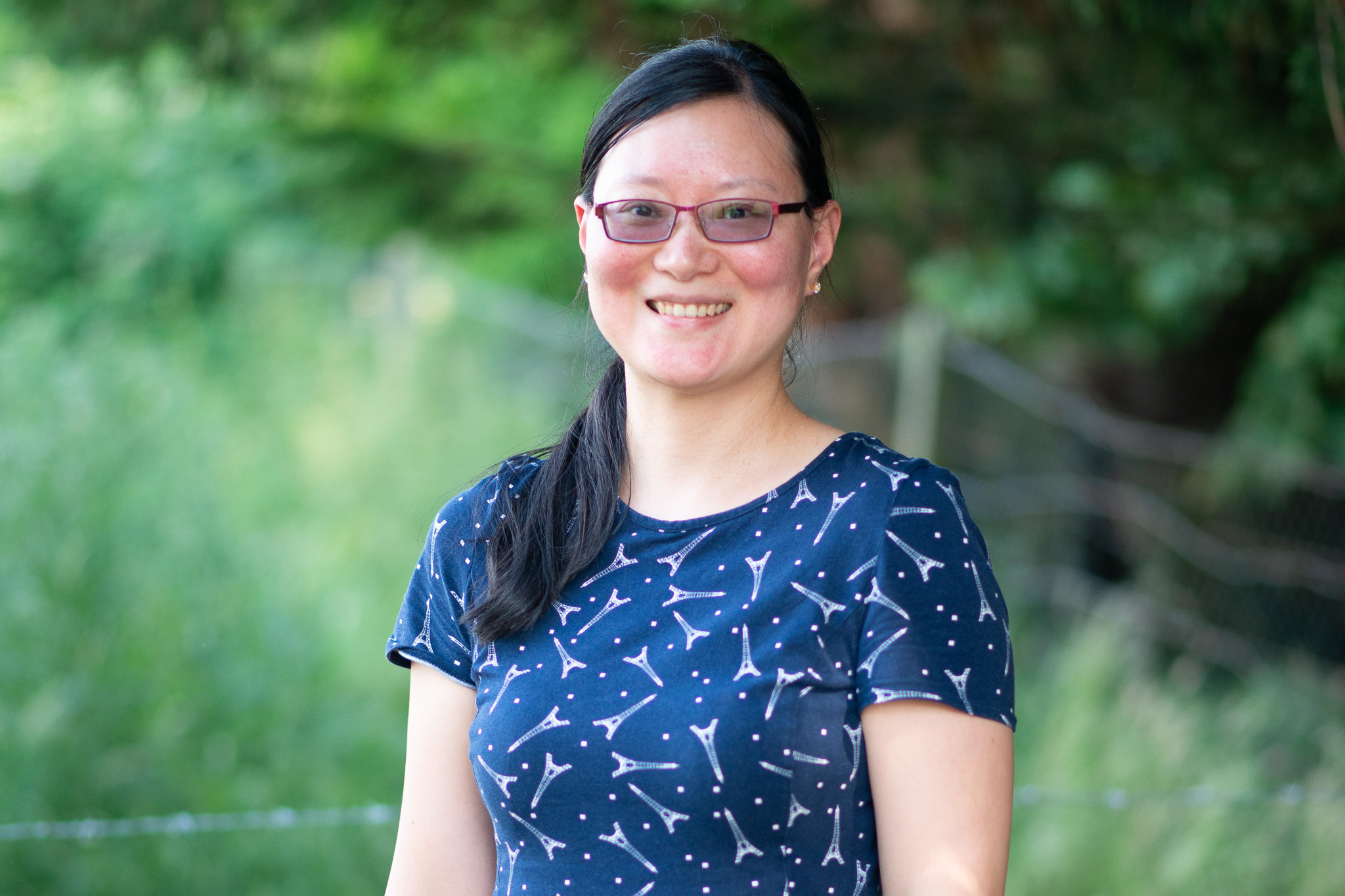

Soon to celebrate her 10 year anniversary with VNC Automotive, we chat to Chunyan White, Technical Account Manager about her role and her latest customer projects.

How long have you been with VNC Automotive and what is your role?

I joined VNC Automotive before it’s spin-out as Presales Applications Engineer in 2014. Over the years, I worked with many global companies in Europe, America, and Asia on numerous projects, helping them bring our technology in their products to market. Starting from evaluating our products, through to training and system integration, certification, and aftermarket technical support, I help the customers every step of the way. I also work closely with the R&D team to bring new feature requests to fruition.

Another essential part of my role is to keep abreast of recent technology trends and put together proof of concept demos that will eventually be part of our standard offerings. I attend international trade shows, host customer demos and training, as well as providing on-site technical support. So all in all, the role is very varied!

“I help customers bring our technology, in their products, to market.”

What is the first thing that you do when you start work in the morning?

I say hello to my colleagues to catch up on things, then get myself a nice cup of coffee and some snacks and work through emails to priorities my day. We have customers all over the world, so it’s common for communications to come in overnight. Although, not all mornings are the same, for example over the last year I have attended trade shows like NAPFM in Telford, showing our products to police and ambulances around the UK, and CES in Las Vegas to promote our journey enhancing connectivity software.

What does a typical day look like for you?

When I am not travelling, I work through emails in the morning to update my to-do list and then go through the list. I typically have meetings with customers next to understand their priorities and update them with our progress. I then spent several hours investigating specific items, this involves meticulously looking through logs and videos provided by the customer and our source code as well as speaking to R&D team to suggest next steps, or request further information. If it requires R&D resources, I then raise these items at the resource planning meetings and fight for a share of the development team resources.

If I can get through all of the immediate and burning customer items, I then work on several R&D proof-of-concept projects in parallel or help improve our latest demos for customer engagements. I work 50% in the office and 50% at home which is common across the company. When I am in the office, lunchtime is almost always the highlight of my day when I enjoy a pleasant stroll with colleagues to get some lunch and then either do puzzles or Lego in the breakout room. The culture is very friendly and supportive here, which we’ve maintained whilst growing the team.

Naming no names, what major projects are you currently working on?

Currently I have been helping a Korean company integrating our Android and iPhone mirroring technology (Cobalt Link+) into their heavy utility vehicles such as cranes and diggers. To help this customer, I have driven a year-long development cycle with many sprints to improve our iOS multi-touch control which will benefit not only this customer but also our Cobalt Cube® customers as well as Cobalt Link+ customers.

In parallel, I have also been working with a UK/Japan company that supplies ruggedised computers to roadside assistance companies, as well as Ambulances and Fire services. Our exciting new Cobalt Cube technology is best suited to mirror their computers on to the vehicle’s OEM screen. My role is to understand their key requirements and drive new feature improvements in line with their sales cycle/opportunities.

What are customers and prospects finding most exciting about our technology right now?

The ability to control everything from the vehicle’s OEM touchscreen is the most exciting technology right now for our first response customers. From police, ambulance and fire services to the roadside assistance and logistics fleets, more and more extra screens and controls are fighting for valuable cabin space, causing clutter and distraction, and becoming hazards in case of collision. Our product Cobalt Cube unifies everything under the built-in OEM screen, which means all the other systems can be hidden away in the boot or behind the dashboard. It is neat, and it is reliable.

Are you reading this and imagining yourself working with Chunyan and the team? Take a look at our careers page and see where your next career move could take you.

VNC Automotive

31st Jan 2024